Cleaning and Restoring Anodized Aluminum

Anodizing is an electrochemical process for producing aluminum oxide coatings on aluminum and its alloys for both decorative and protective purposes. The oxide coating is integral with the aluminum therefore it will not chip, peel or flake. The oxide coating creates a surface that is harder, abrasion resistant, increases the natural corrosion resistance of the aluminum and allows the finish to be decoratively colored.

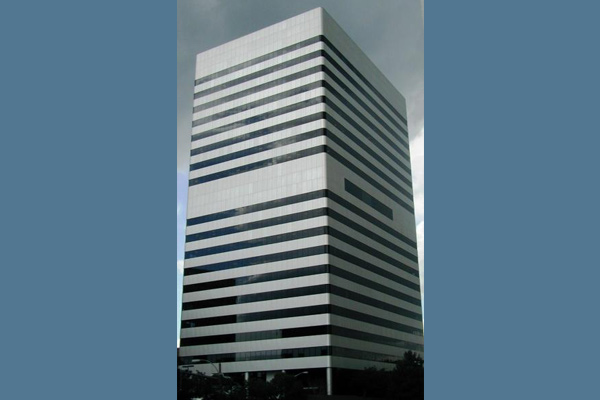

Initially, anodized aluminum was marketed as a maintenance free material by the aluminum manufacturers and finishers. It became readily apparent that architectural aluminum was affected by weathering and exposure to natural elements and atmospheric pollutants. The combination of surface soil and these contaminants can accelerate the surface roughening, staining and discoloration of the finishes. In advanced stages of exposure, corrosion in the form of pitting may develop.

Building Maintenance is Key to Architectural Preservation

The decorative metallic appearance of these finishes can only be preserved by periodic cleaning and maintenance. If the aluminum curtain wall has been neglected for extended periods of time, a labor intensive restoration cleaning will be necessary. Restoration cleaning may require the use of abrasive cleaning methods to remove the heavy pollutants, contaminants and oxidation that have developed over a period of years followed by the application of a clear surface protectant. This proprietary protectant improves the weathered appearance of the finish and protects it from environmental and atmospheric pollutants and surface degradation. Implementation of a technically sound restoration and maintenance program will ensure that the surface appearance of these Class 1 architectural finishes can be preserved indefinitely.